To grow older is to grow better.

That seems to be the case with our buddy Paul. He recently hit a landmark birthday, 70 I believe, and to enjoy an early wake with the living not-fully-yet-deceased 5 of us headed north to attempt to pickle him in beer. Even if the preservation effects wouldn’t last forever, we knew we’d have a lot of fun. Paul set the agenda and we were along for the ride so here’s what happened in the order I remember.

For all the glory the Airport Authority totes about their new fancy-pants Terminal 2, we left out of the 1960’s standard of Terminal 1 on the winged glory bus of Southwest into Oakland. The beer selection out of Terminal 1 and their temp bar continues to lack but a Lightening Elemental Pils really hit the spot. We arrived, got our vehicle and burned rubber upto Santa Rosa. Dumping our car and bags off at the hotel we hopped in a few cabs to Russian River brewpub. And the dispatcher lied, “We don’t have minivan cabs” as the 2nd cab to pick us up was, in fact, a minivan.

After a brutal, dry wait at the bar for 1 1/2hrs we, as Vinnie put it later, got the best table in the house. During that trying time many a pint of Blind Pig, PtE and Row 2, Hill 456 were consumed. It was tough, it was hard…who am I kidding, I barely realized how long we’d been waiting. Aside from all the usual fantastic world-class beer on tap they had 3 special beers, Propitiation (sour porter), Shadow of a Doubt & Huge Large “Sound Czech” Pils were on tap. RRBC makes to lagers, this one named for Vinnie’s favorite band “Huge Large” and the other Great Beer/Great Wine…which shows up on BA as an APA but I thought during our tour Vinnie said it was a lager.

Being an unashamed tourist and the fact they had special glassware for the Huge Large I ordered up a “Round of Boots!” for our table, also making good souvenirs:

Quite freshing, .5L boots of pils! And into the night the sours and imperial porters came and went. The proper minivan cab was our ride home.

Friday “A tale of two breweries, methodologies and philosophies”

Russian River production facility vs. Moonlight Brewing facility.

After a hearty breakfast at the hotel we rallied and were at RR production facility at the crack of 11am. Vinnie met us and started our day off right, 8 day old PtE. We sat in the worker’s bar and got to know each other. Many questions were passed about Rip Current’s startup status and some factoids about this facility. At one point this location was going to be opened to the public but due to production disruptions tours may have caused the idea was discarded. However, they do have a nice little bar onsite.

About 10 people work at the production facility on a given day.

What we learned was this brewery had a lot of its hot side bought from Dogfish Head after they did a major expansion. Vinnie & Crew tweaked it and squeezed out better efficiency than it was producing on the east coast. Further, when they do their next expansion it was my understand they intend to sell this facility turn-key and build a custom brewery from the ground up. Something akin to what Green Flash and Stone did during their expansions.

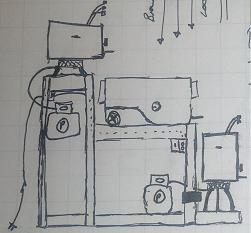

Not pictured are the keg washer using sanitary steam and the de-airing watering system they use to flush their system with to avoid all possibility of picking up oxygen into the beer.

In fact, much of the tour was about eliminating sources for dissolved oxygen (DO) entering the beer during any phase of production. Avoiding DO seems to be one of Vinnie’s quests as a brewer and now that they’re in the black they can afford the more expensive toys to eliminate DO. Maybe this attention to detail is what sets RRBC on a level above most others?

Or maybe it’s all these barrels…temp controlled and I could have crawled in there and lived a happy life. The small conical is a test batch of new line of beers RRBC intends to release later. More tech talk about production, hop ordering and details of the brewery that I’ve since forgotten. Before leaving we sampled an experimental beer for the coming line as they work out the details. Lesson learned, good beer is dry beer and they try to finish most of their non-sours out at 1.008.

Paul setup a tour of Moonlight Brewing for us next. After nearly getting lost (sort of) we drove out to the ‘hop farm’ in the middle of wine country. Brian Hunt met us in the drive way and after introductions we got the tour of the brewery. “You’ve been to a brewery before? Well, this is it.” And that was the tour. Which frankly, was all you needed. Unless a brewery is doing something radically different 95% of all breweries pretty much operate the same.

I did learn his brewhouse was built in the late 70’s and he uses grundies as his main lagering tanks.

It is very difficult to photograph Moonlight’s cold room. After Brian poured our first samples we headed out to the drive way and grabbed chairs under a tree to talk. Unlike the specific technical brewing details of RRBC, Moonlight was much more relaxed.

I asked about zoning since he was brewing on what appeared to be residential property. Was told his land is zoned for dual purpose, if he process his crop (hops) onsite then he can produce beer. I don’t believe he’s much of a fan of growing hops but it’s the nature of his situation.

One of the stories Brian told us was the history of Grundy (7bbl) tanks leaving pubs in England and coming to the US. Which is how he came to use them in his cold room. The county would only allow him to build a 1 story brewhouse, so he made it as tall as they’d allow and then built a tall cold room where he welded vertical grundies 2 high. The top ones are used for long term conditioning since he doesn’t care to get up there and clean them often.

Pour samples from horizontal grundies, 4 wide and 4 tall. One thing Brian does with his wet hops is to, of course, make a wethop beer, then after racking it to kegs he transfers over his Christmas ale and lets it sit there until it’s time to keg it, about a year later.

Brian is a man brewing beer on his terms, not in a rush, and brewing the way he’s always brewed. He still delievers most of his kegs to his accounts and might bottle at the new location. I also wouldn’t ask him what any ‘style’ of beer his is, you’ll end up in a 30 minute lecture about “Norwegian Style” beer. This was by far one of my personal highlights of the trip. The difference in styles of brewing between these two breweries spanned the entire spectrum.

If you’ve heard Moonlight is going to open a tasting room, it’s true. He’ll be moving his brewing facility from the Hop Field location elsewhere. Brewing here seems to be at the end of an era. He did not give details as to when the tasting room would be open.

Next up is Lagunitas, unfortunately after walking in I was having a case of the bottle flu and returned to the car to nap. The previous night I may have been over served and it caught up with me. I’m told the rest of the guys had a great time sampling various beers and took a tour of the new 250bbl brewhouse. Being in the best shape some 2hrs later I drove us back to the hotel where we caught a cab back to RRBC pub.

Dinner and only 2 beers each we were tired and cashed it in. This wraps up our Santa Rosa portion of the trip.

Saturday

After another healthy bacon infused breakfast we headed over to Napa to visit Downtown Joe’s.

Tour of the brewhouse by Joe himself. A 7bbl pub system installed 20 something years ago by Brian Hunt. We thought the stacked grundy cold room looked eerily familiar!

Some decent beer, nothing to get too excited about but not a place worth avoiding if you’re stuck drinking grape juice all day. We had a light lunch here and then headed back to Oakland to check in to our last hotel.

We then caught the BART to City Beer using BeerbyBart.com and met up with Steve and Gail who run said website. Place is totally different from the last time I was here several years ago. Some interesting beer on tap and of course lots of bottles but nothing we can’t find in San Diego. In fact some of the best beer on tap was our local flavor. From here we walked through the ghetto, thankfully it was broad daylight, to get over to the new Mikkeller Bar. We stood in a short 10 minute line to get in. During that time we watched the corner drug dealer sell his crack and watched his clients smoke it as fast as possible.

Not exactly in the best part of town, watch your step for bodies and muggers.

About 40 taps plus the cellar in the basement. Which unfortunately gets hot when there are many people down there. A long list of imported beers and rare sours. The only IPA was from Ninkasi and several offerings had kicked without being replaced.

Prices were high and that was a major turnoff, but I’m told for some of the beer being offered Stateside it was a pretty good deal. I stuck to a few barrel aged beers and enjoyed one Cantillion.

Ever the salesman, Paul spent time speaking Mikkel and built a friendship. Mikkel is asking for Rip Current kegs for his stateside bars. Woot!

After this we headed back to Oakland via BART and hit up the Trappist. I had a much better time here and loved the location. A table was easily found and we had a light dinner here. I can’t remember the beer we had but none was lacking. Just after 10 we started the walk through the ghetto to Beer Revolution only to be told they had called last call and they closed at 11. Which seems crazy earlier but the doorman directed us to the Oude Depot next door.

Apparently the husband/wife team that ran Beer Rev divorced and she opened up a beer joint next door that’s open until 1am. No frills here, just a straight up bar thrown together. Decent and deep tap list kept us happy and we finished up around 12am.

A walk back past the Oakland Police station got us home.

Sunday

Final day had us checking out and headed up to the Triple Rock Brewpub. Sara was our server and a native of San Diego north county. A lunch and a few beers of which the APA and IPA were found to be favorites. Throughout our trip we’d been ordering quite a few half pints, more than a taster but without all the commitments that ride with a pint. She found this hilarious that ‘pro brewers’ drank half pints and was a personal vindication since she was made fun of by the other staff.

Final stop before heading to the airport to return home. Many good beers on tap and no brewery tour. We met Tasty McDole of the Brewing Network here and worked our way through their barrel aged beers and sours.

The weather was absolutely perfect for Alex to catch a sunburn on 1 leg and the rest of us to wind down before the flight home.

Tasty’s parting words “Have a good flight back, your beer scene down there is better than ours.”

All in all a fantastic trip and a great way to celebrate Paul’s birthday!